Description

| Parameter | Specification |

|---|---|

| Sensor Type | PID (Photoionization Detector) |

| Detected Gases | Solvent vapors / VOC mixtures |

| Measurement Range | 0 – 1000 ppm (VOC, factory calibrated) |

| Output Signals | 4–20 mA / RS-485 (Modbus RTU) |

| Power Supply | 24 V DC |

| Response Time | < 30 seconds |

| Operating Temperature | 0 to +50 °C |

| Operating Humidity | 0–95% RH (non-condensing) |

| Enclosure Protection | IP65 |

| Mounting | Wall or panel mounted |

| Calibration Interval | Typically every 6–12 months, depending on usage |

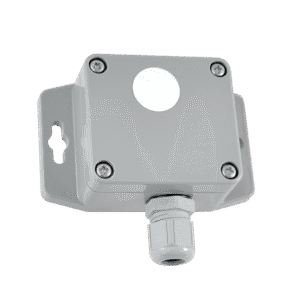

A solvent vapors detector is a specialized gas monitoring device used to identify and measure the concentration of volatile organic compounds released from solvents. These vapors can pose serious health, fire, and process-contamination risks. A high-quality solvent vapors transmitter like the E2618-VOC continuously measures vapor levels and sends real-time data to control systems, enabling rapid response before conditions become unsafe. In advanced industries such as pharmaceuticals, semiconductors, and aerospace, accurate solvent vapor detection is essential for worker safety and process integrity.

The water vapour transmission rate (WVTR) measures how much water vapour passes through a material over time. The simplified formula is:

WVTR = (ΔW) / (A × t)

Where ΔW is weight change, A is surface area, and t is time. While WVTR is mainly used in packaging and materials science, understanding vapour transmission principles supports better control of solvent vapors in controlled environments.

Common solvents used in solvent extraction include ethanol, methanol, hexane, acetone, and isopropyl alcohol. The choice depends on polarity, safety, and process requirements. Because many of these solvents release hazardous vapors, a reliable solvent vapors detector is critical for monitoring exposure levels during extraction processes.

Solvent extraction works by dissolving a target compound from a solid or liquid matrix into a suitable solvent. The solvent selectively separates the desired component, which is later recovered. During this process, solvent vapors are often released into the air, making continuous monitoring with a vapor detector essential to maintain safe working conditions.

In the UAE and wider GCC, advanced manufacturing, aerospace MRO, and pharmaceutical industries are expanding rapidly. These facilities rely heavily on solvents while operating under world-class safety standards. High temperatures and enclosed workspaces increase vapor risks, making accurate solvent vapors sensor technology vital. The E2618-VOC helps organizations meet strict HSE requirements while protecting high-value production environments.

How Often Do Gas Detectors Need to Be Calibrated?

Most gas detectors, including solvent vapors transmitters, should be calibrated every 6 to 12 months. In high-risk or high-usage environments, more frequent calibration ensures accuracy and compliance with safety standards.

Why choose us?

Ensure reliable solvent vapor monitoring in your facility with the E2618-VOC Solvent Vapors Transmitter.

Gas Detectors UAE is your trusted hydrogen gas detection suppliers in UAE and Authorised Distributor of Evikon.

Contact us today to request pricing, technical guidance, or a customized safety solution for your operation.

Reviews

There are no reviews yet.