Description

| Parameter | Specification |

|---|---|

| Detected Gases | Halocarbon refrigerants (HFC types) |

| Sensor Type | Metal-oxide semiconductor |

| Measurement Principle | Diffusion |

| Output Signal | Analog 4–20 mA / 0–10 V (model dependent) |

| Power Supply | 24 V AC/DC |

| Mounting | Wall mount |

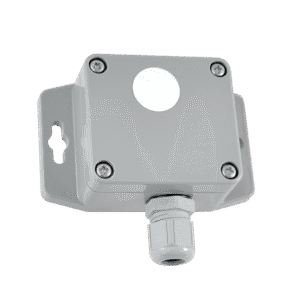

| Enclosure | Industrial ABS housing |

| Operating Temperature | Suitable for typical HVAC and industrial indoor environments |

| Application Areas | HVAC rooms, cold storage, laboratories, cleanrooms |

A refrigerant detector is a safety device used to identify leaks of refrigerant gases from HVAC and refrigeration systems. These gases, while essential for cooling, can become hazardous when they accumulate in enclosed spaces. A refrigerant detector or refrigerants transmitter continuously samples ambient air and converts gas concentration into an electrical signal for monitoring systems. This allows facility managers to act quickly, reducing risks to personnel, preventing equipment damage, and ensuring compliance with safety regulations. In environments like laboratories, cleanrooms, and industrial plants, early detection is critical for uninterrupted operations.

Most modern air-conditioning systems use HFC refrigerants such as R-410A, R-32, or R-134a. These refrigerants provide efficient cooling and are widely used in commercial and industrial HVAC systems due to their reliability and performance.

Refrigerators commonly use refrigerants like R-134a, R-404A, and newer low-GWP alternatives depending on system size and application. Industrial refrigeration systems often rely on blends that balance efficiency and safety.

Refrigerant gases are generally grouped into CFCs, HCFCs, HFCs, HFOs, and natural refrigerants. Each type differs in environmental impact, safety profile, and operating pressure, making proper monitoring essential.

Why It Is Essential in the UAE & GCC

In the UAE and GCC, extreme ambient temperatures, large HVAC systems, and strict safety standards make refrigerant monitoring critical. Facilities in aerospace, pharmaceuticals, and advanced manufacturing depend on uninterrupted cooling. A reliable refrigerant transmitter helps prevent costly shutdowns, supports compliance, and protects high-value assets in these fast-growing sectors.

How Often Do Gas Detectors Need to Be Calibrated?

For reliable operation, refrigerant detectors and transmitters should be calibrated at least once every 12 months. Regular calibration ensures accuracy, supports compliance, and extends the operational life of the sensor.

Why choose us?

Upgrade your refrigerant safety strategy today with the Evikon E2618-HFC Refrigerant Transmitter.

Contact Gas detectors UAE — trusted hydrogen gas detection suppliers in UAE and Authorised Distributor of Evikon — for expert advice, fast delivery, and dependable after-sales support. Request a quote now and protect your facility with confidence.

Reviews

There are no reviews yet.