Description

| Specification | Details |

|---|---|

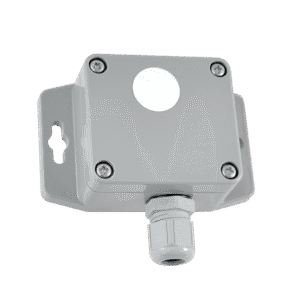

| Brand | Evikon |

| Model | E2630-LEL Combustible Gas Detector |

| Sensing Technology | Catalytic bead |

| Gases Detected | Methane, Propane, Butane, Hydrogen, LPG, and other combustibles |

| Measurement Range | 0…100% LEL |

| Output Signals | 4–20 mA, 0–10 V, Modbus RTU |

| Power Supply | 12–24 V DC |

| Response Time (T90) | < 30 seconds |

| Operating Temperature | –20…+50 °C |

| Operating Humidity | 15–95% RH, non-condensing |

| Ingress Protection | IP65 industrial enclosure |

| Mounting | Wall-mount |

| Housing Material | ABS/Polycarbonate |

| Dimensions | 112 × 95 × 56 mm |

| Certifications | CE |

A combustible gas transmitter is a fixed industrial device that continuously measures the concentration of explosive gases in the air. It is installed in areas where fuels such as methane, propane, hydrogen, or acetylene may be present. The transmitter converts gas levels into an electrical output that connects with alarms or control systems. Its purpose is to warn personnel and prevent fires, explosions, equipment shutdowns, and contamination of sensitive processes.

In industries like semiconductor fabrication, pharmaceutical biotech labs, aerospace engineering, and hydrogen facilities, a combustible gas transmitter is considered a mandatory safety tool. It provides constant monitoring to ensure that gas levels remain well below the Lower Explosive Limit (LEL), creating a safer working environment.

Most combustible gas sensors use catalytic bead technology. When flammable gas comes into contact with the heated bead inside the sensor, it oxidizes and produces heat. This heat changes the bead’s electrical resistance. The transmitter measures this resistance and converts it into a gas concentration level. This simple but highly reliable process allows continuous, accurate monitoring.

For industrial facilities, offshore platforms, and aviation maintenance sites, it is recommended to carry at least one portable multi-gas detector per working team. In high-risk or confined spaces, each technician should have their own detector. This ensures rapid personal protection and compliance with safety regulations.

There are four main types of gas detectors:

-

Fixed gas detectors (for continuous area monitoring)

-

Portable multi-gas detectors (for worker safety)

-

Single-gas detectors (targeting one gas only)

-

Wireless gas detection systems (for remote or mobile monitoring)

Each type serves different safety and operational needs depending on the industry.

The UAE and GCC are rapidly expanding sectors such as aerospace manufacturing, hydrogen production, semiconductors, pharmaceuticals, and energy. These industries involve flammable gases that pose significant risks if not monitored. High-value facilities in Abu Dhabi, Dubai, and Saudi Arabia require reliable combustible gas monitors to meet global safety standards. Strict regulations, world-class manufacturing goals, and environmental compliance make the Evikon E2618-LEL a necessity in the region.

Why choose us?

For advanced combustible gas monitoring that protects your workforce and critical operations, choose the trusted experts.

Gas Detectors UAE is the leading supplier of hydrogen and combustible gas detection systems in the UAE and the Authorised Distributor of Evikon.

📞 Contact us now for pricing, expert consultation, or bulk orders tailored to your facility.

Reviews

There are no reviews yet.