Hydrogen is becoming increasingly important as industries shift toward cleaner energy and sustainable solutions. However, with its benefits comes a significant challenge: its invisible and highly flammable nature makes it a significant safety risk. An undetected hydrogen gas leak can lead to catastrophic explosions, financial loss, and severe injuries.

This guide, written from an engineer’s perspective, explains the dangers of hydrogen gas, the principles of effective detection, and how to implement a robust safety strategy.

Without an effective hydrogen gas leak detector, industries risk catastrophic explosions, workplace injuries, and non-compliance with safety standards. For MEP contractors, firefighting companies, and facility managers across the UAE, hydrogen gas detection systems are no longer optional—they are a necessity.

Table of Contents

The Silent Danger: Why is Hydrogen Gas So Dangerous?

Understanding the properties of hydrogen is the first step toward mitigating its risks. Unlike natural gas, which has a distinct odorant added for detection, hydrogen is colorless and has no hydrogen gas smell, making it impossible to detect with human senses alone. This is where the hydrogen leak danger truly lies.

Unmatched Flammability and Explosive Potential

Hydrogen is the most flammable element in existence. It can ignite with incredibly low energy—far less than a spark of static electricity. It has a very wide explosive range, meaning it can ignite in concentrations from 4% to 75% in the air. This combination makes a hydrogen gas leak explosion a severe and immediate threat in any facility where it’s used or stored.

The Risk of Asphyxiation

While the primary concern is fire, a significant hydrogen leak in a poorly ventilated area can displace oxygen. This creates an asphyxiation hazard for any personnel in the vicinity. The lack of oxygen can cause dizziness, unconsciousness, and, ultimately, death without any warning signs.

Invisible and Odorless: The Sensory Gap

You cannot see, smell, or taste hydrogen gas. This “sensory gap” means that by the time a leak is large enough to cause physical symptoms like a changed voice pitch, the concentration might already be well within the explosive range. Relying on human senses is not a safety strategy; it’s a gamble. This is precisely why a professional hydrogen gas detection system is not just a recommendation—it’s a necessity.

This is why facility managers and engineers often ask: “Is hydrogen gas dangerous?” The answer is a clear yes, and proper hydrogen gas detection sensors are the only effective preventive measure.

The Core of Safety: Understanding Hydrogen Gas Detection Systems

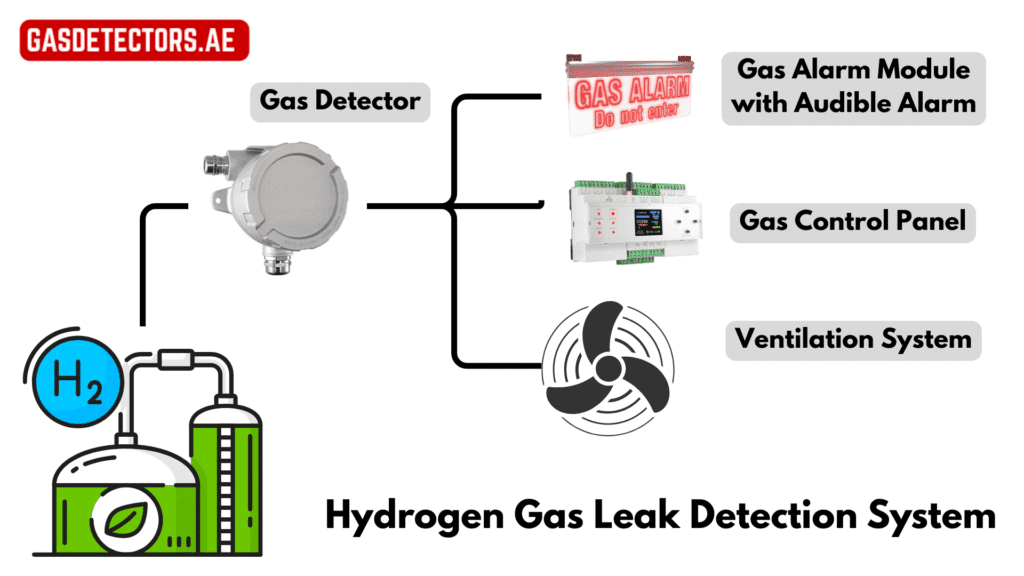

So, how to detect hydrogen safely and reliably? The answer lies in specialized gas detection technology. A gas leakage detection system is an automated network of sensors and alarms designed to provide constant monitoring and immediate alerts.

Hydrogen Gas Detector Working Principle

At its core, a hydrogen gas leak detector works by continuously sampling the air. A sensor inside the device is designed to react specifically to the presence of hydrogen molecules. When hydrogen concentration exceeds a pre-set safety threshold (measured in % LEL – Lower Explosive Limit), the sensor triggers an alarm. This alarm can be audible, visual, or connected to a central control panel that can automatically initiate safety protocols, such as activating ventilation control systems or shutting down processes.

Key Types of Hydrogen Gas Detection Sensors

Several types of hydrogen gas detection sensors are available, each with its own strengths:

- Catalytic (Pellistor): These sensors are a reliable and cost-effective choice for detecting combustible gases like hydrogen. They operate by oxidizing the gas on a heated catalyst bead, which changes the resistance of an internal circuit and triggers an alarm.

- Metal-Oxide Semiconductor (MOS): MOS sensors offer high sensitivity and a very long operational life. They detect gas through a change in conductivity when gas molecules interact with the surface of a heated semiconductor. They are known for their durability in harsh industrial environments.

- Electrochemical: These sensors are highly specific to a particular gas and are excellent for detecting low concentrations, although they are more commonly used for toxic gases.

The right sensor depends on your specific application, environmental conditions, and budget.

Featured Solution: Evikon E2670-LEL Flameproof Combustible Gas Detector

For facilities that demand the highest level of safety and reliability, we recommend the Evikon E2670-LEL Flameproof Combustible Gas Detector. Engineered in Estonia by Evikon, a leader in sensor technology, this detector is specifically designed for harsh and hazardous environments, making it the ideal hydrogen gas leak detector for industries in Dubai, Abu Dhabi, and across the UAE.

Why Choose the E2670-LEL for Hydrogen Detection?

The Evikon E2670-LEL is more than just a detector; it’s a critical safety asset. Its robust design and advanced technology provide peace of mind and seamless integration into your existing safety infrastructure. The flameproof enclosure ensures the device itself cannot become an ignition source, a vital feature when dealing with highly combustible gases like hydrogen.

Benefits

- Provides early warning of hydrogen leaks, reducing explosion risks.

- Built with flameproof enclosure, suitable for hazardous areas.

- Compatible with ventilation control systems for automatic response.

- Designed for industrial durability and long-term use.

Key Technical Features

- ATEX Certified: Suitable for use in potentially explosive atmospheres (ATEX Zones 2 and 22), providing certified safety.

- Multiple Sensor Options: Utilizes long-life MOS or pellistor gas sensors for excellent repeatability and stability.

- Robust Enclosure: Housed in a die-cast aluminum casing with an IP66 rating, ensuring protection against dust and water ingress.

- Flexible Integration: Features two analog outputs (settable to 4-20 mA or 0-10 V) and an RS485 Modbus RTU digital interface for easy connection to building automation or safety systems.

- Configurable Alarms: Comes with optional internal relays with user-settable alarm points for activating local alarms or ventilation systems.

- Wide Detection Range: Detects a range of combustible gases, including hydrogen, methane, propane, and butane, making it a versatile solution.

Common Applications

The Evikon E2670-LEL Flameproof Combustible Gas Detector is the perfect solution for:

- Battery Charging Rooms: A critical tool for hydrogen gas detector installation in battery room environments where hydrogen is a byproduct of charging lead-acid batteries.

- Oil and Gas Facilities: Essential for upstream, midstream, and downstream operations where a gas leak can have devastating consequences.

- Power Plants & Energy Storage: Protects facilities that use hydrogen for cooling or in fuel cell applications.

- Industrial Manufacturing: For any process involving hydrogen as a raw material or byproduct.

- Laboratories and R&D Facilities: Ensures the safety of personnel working with hydrogen gas.

Immediate Action: What to Do if You Suspect a Hydrogen Gas Leak

If an alarm sounds or you suspect a leak, follow these steps immediately:

- Do NOT create an ignition source: Do not turn any lights or electrical equipment on or off. Do not use a phone.

- Extinguish all open flames.

- Evacuate the area: Follow your facility’s emergency evacuation plan calmly and quickly.

- Ventilate (if safe): If you can do so without creating a spark, open doors and windows to disperse the gas.

- Call for help: From a safe location, contact your facility’s emergency response team and the local fire department.

Proactive Protection: Essential Preventive Measures

The best way to handle a gas leak Dubai or Abu Dhabi incident is to prevent it from happening. A multi-layered approach is key.

Implement Robust Ventilation Control Systems

Proper ventilation is your first line of defense. It helps prevent hydrogen from accumulating to dangerous concentrations. Your ventilation system should be designed by professionals and integrated with your hydrogen gas detection system to automatically increase airflow when low levels of gas are detected.

Strategic Hydrogen Gas Detector Installation

Correct placement is crucial. Hydrogen is the lightest element, so it rises and accumulates at the highest point of a room or enclosure. Detectors should be installed at ceiling level, directly above areas where a leak is most likely to occur, such as valves, fittings, and storage tanks. This is particularly important for hydrogen gas detector installation in battery room settings.

The Critical Role of Professional Calibration

A hydrogen gas detector is only effective if it is accurate. Hydrogen gas detector calibration is a mandatory, routine process where the sensor is tested against a known concentration of hydrogen gas to ensure it provides correct readings. This service must be performed by certified technicians at regular intervals (typically every 6-12 months) to comply with safety standards and ensure your system is always ready to respond.

Hydrogen Gas Detection Systems in UAE: Standards and Compliance

In the UAE and GCC, hydrogen gas detection (as applicable) is regulated by:

- Dubai Civil Defense (DCD) requirements

- Oil & Gas industry HSE standards

- International guidelines (NFPA, ATEX, IECEx)

Installing a certified hydrogen gas leak detector is not only about safety—it’s about meeting legal and contractual requirements. Contractors who fail to install these systems risk penalties, rejected inspections, and reputational damage.

Your Questions Answered: FAQs on Hydrogen Gas Leak Detection

1. Is hydrogen gas dangerous?

Yes, is hydrogen gas dangerous is a critical question. It is extremely dangerous due to its wide flammability range (4-75% in air) and very low ignition energy. An undetected leak can easily lead to a fire or a powerful hydrogen gas leak explosion. Furthermore, it is an asphyxiant in high concentrations, as it displaces oxygen. Its odorless and colorless nature makes it impossible to detect without specialized equipment like a hydrogen gas leak detector.

2. How can you test for hydrogen gas?

You cannot safely test for hydrogen gas with manual or homemade methods. The only safe and reliable way is to use a calibrated electronic hydrogen gas detector. These devices continuously monitor the air and provide an immediate alarm if hydrogen concentrations exceed a safe level. Professionals may use portable detectors for pinpointing leaks during maintenance, but for continuous safety, a fixed hydrogen gas detection system is essential.

3. What is a gas leak detector?

In simple terms, what is a gas leak detector is a device that identifies the presence of specific gases in the air. For hydrogen, the detector’s sensor is designed to react to H2 molecules. When the concentration reaches a pre-set alarm level, it triggers an alert. These systems are the cornerstone of safety in any facility that handles combustible or toxic gases, providing the early warning needed to prevent disasters from a leak gas situation.

4. Does hydrogen gas smell?

No, pure hydrogen gas has no smell. Some people might report a faint metallic odor during electrolysis, but this is due to impurities, not the hydrogen itself. The lack of a natural hydrogen gas smell is a major reason why it is so hazardous. You cannot rely on your nose to detect a leak, making a reliable hydrogen gas detection sensor absolutely necessary for safety.

5. What is the working principle of a hydrogen gas detector?

The hydrogen gas detector working principle depends on the sensor type. Most commonly, catalytic or MOS sensors are used. A catalytic sensor oxidizes (burns) the hydrogen on a heated element, causing a change in electrical resistance that triggers an alarm. A MOS sensor detects changes in conductivity on a semiconductor’s surface when hydrogen is present. Both methods provide a reliable electronic signal that is proportional to the gas concentration.

6. Why is detector installation in a battery room so important?

Hydrogen gas detector installation in battery room environments is critical because charging lead-acid batteries produces highly flammable hydrogen gas as a byproduct. Without proper ventilation and detection, this gas can accumulate at the ceiling. A single spark from equipment or static electricity could ignite the gas. A properly placed hydrogen gas detection unit provides an essential early warning to prevent such an incident.

7. How to detect hydrogen if it has no color or odor?

The only reliable answer for how to detect hydrogen is through a dedicated hydrogen gas detection system. Since you cannot see or smell it, you must rely on technology. These systems use specialized sensors that are calibrated to identify hydrogen molecules in the air. They provide constant, 24/7 monitoring, which is something human senses can never achieve, protecting against the invisible hydrogen leak danger.

8. What is the average hydrogen gas detector price?

The hydrogen gas detector price can vary significantly based on the technology, features, and certifications. The total cost of a full gas leakage detection system also includes installation, cabling, and a central controller. However, the cost of a detector is nothing compared to the potential cost of an accident.

9. How often should a hydrogen gas detector be calibrated?

Hydrogen gas detector calibration is essential for ensuring accuracy and reliability. Industry best practices and manufacturer recommendations typically require calibration every 6 to 12 months. The frequency can depend on the operating environment; detectors in harsher conditions may require more frequent checks.

Regular calibration ensures the sensor responds correctly to gas and is a standard requirement for maintaining safety compliance in facilities.

10. Can a hydrogen leak cause an explosion?

Yes, absolutely. A hydrogen gas leak explosion is one of the primary dangers associated with the gas. Hydrogen has a very wide explosive range, meaning it can ignite when mixed with air in concentrations from as low as 4% to as high as 75%. It requires very little energy to ignite. An undetected leak can quickly fill a space with an explosive mixture, waiting for a small spark to trigger a devastating event.

11. Who supplies hydrogen gas detection systems in UAE?

Gas Detectors UAE is the authorised distributor of Evikon in Dubai and GCC, providing certified detectors with installation, testing, commissioning and post sales support.

GASDETECTORS.AE : Your Trusted Partner for Hydrogen Gas Safety in the UAE

Protecting your facility, assets, and personnel from the dangers of hydrogen gas requires expertise and the right equipment. As the leading hydrogen gas detection suppliers in UAE, we provide comprehensive solutions tailored to your specific needs.

We are the Authorised Distributor of Evikon, Estonia, ensuring you get world-class technology backed by local expertise. From system design and product selection, like the robust Evikon E2670-LEL Flameproof Combustible Gas Detector, to professional installation and calibration services, we are your end-to-end safety partner.

Don’t wait for an incident to occur to start thinking about safety.

Contact our engineering team today for a free consultation or to request a quote. Secure your facility with the best hydrogen gas detection systems on the market.