Description

| Parameter | Specification |

|---|---|

| Sensor Type | Electrochemical |

| Target Gas | Ethylene Oxide (EtO) |

| Measurement Range | 0 – 100 ppm (typical) |

| Output Signals | 4–20 mA, RS-485 |

| Power Supply | 24 V DC |

| Response Time | < 30 seconds |

| Operating Temperature | −40 °C to +50 °C |

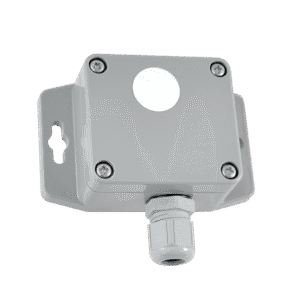

| Housing | Industrial-grade enclosure |

| Mounting | Wall mount |

An ethylene oxide detector is a fixed gas monitoring device used to detect and measure ethylene oxide gas in the air. Ethylene oxide is toxic, flammable, and highly reactive, making continuous monitoring essential wherever it is used or stored. The ethylene oxide sensor measures gas concentration and sends a signal through an ethylene oxide transmitter to alarms or control systems.

This helps facilities comply with exposure limits outlined in ethylene oxide MSDS guidelines and reduces risks linked to uncontrolled ethylene oxide reactions. Such detectors are vital in pharmaceutical sterilization units, biotech labs, and high-purity manufacturing environments.

Ethylene is produced mainly through steam cracking of hydrocarbons like ethane or naphtha. These materials are heated to very high temperatures, breaking chemical bonds and forming ethylene gas. This ethylene is then used as a base material to produce ethylene oxide and other industrial chemicals.

Ethylene glycol is used as an antifreeze because it lowers water’s freezing point and raises its boiling point. This helps cooling systems operate safely in extreme temperatures, preventing freezing in cold conditions and overheating in hot environments.

Ethylene oxide is widely used for medical device sterilization, production of ethylene glycol, and manufacturing of surfactants and specialty chemicals. Due to its hazardous properties, continuous monitoring with an ethylene gas sensor is critical to maintain safe working conditions.

Why It Is Essential in the UAE & GCC

The UAE and GCC are rapidly expanding their pharmaceutical, healthcare, and advanced manufacturing sectors. Ethylene oxide sterilization is common in these industries, while high ambient temperatures can increase gas exposure risks. The Evikon E2648-ETO Ethylene Oxide Detector supports world-class HSE standards and helps protect people, processes, and high-value facilities aligned with the region’s economic diversification strategy.

Calibration Frequency

Ethylene oxide gas detectors should typically be calibrated every 6 to 12 months, depending on site conditions, gas exposure, and safety regulations. Regular calibration ensures the ethylene oxide detector delivers accurate and reliable readings over its service life.

Why choose us?

Protect your facility with precise and dependable ethylene oxide monitoring. Gas Detectors UAE is your trusted hydrogen gas detection suppliers in UAE and Authorised Distributor of Evikon.

Contact us today for expert advice, fast delivery, and competitive pricing on the E2648-ETO Ethylene Oxide Detector.

Reviews

There are no reviews yet.