Table of Contents

Introduction: The Unseen Threat in the MRI Room

The Magnetic Resonance Imaging (MRI) technology stands as a monument to medical technology, offering unparalleled diagnostic capability. However, this critical medical space harbors a singular, catastrophic safety risk rooted in its very operating principle: the use of cryogenic liquids.

To achieve the powerful magnetic fields required for scanning, MRI machines use supercooled magnets bathed in cryogens, typically Liquid Helium (LHe) or, in some older systems, Liquid Nitrogen (LN₂). These liquids are stored at extremely low temperatures (near absolute zero).

The danger arises from a sudden system failure known as a Quench. A quench occurs when the magnet loses its superconductivity, causing the liquid cryogen to rapidly boil off and transition from a liquid to an enormous volume of gas.

This massive release of gas poses an immediate and deadly threat: Oxygen Deficiency. Since the escaping cryogen gas is inert and heavy, it instantly displaces the breathable air in the room, creating an atmosphere incapable of supporting life. Within seconds, the oxygen levels can plummet from the safe level of 20.9% to below 16%.

For hospital facility managers and safety officers in the highly regulated UAE and GCC environment, implementing a fast, reliable, and compliant Oxygen Deficiency Monitoring MRI system is not optional—it is a mandatory life safety requirement essential for protecting patients, staff, and the facility’s accreditation status. This guide provides the technical and regulatory framework necessary to ensure total safety and compliance in your MRI suite.

The Cryogen Hazard: Why O₂ Levels Plummet in Seconds

To fully appreciate the need for dedicated MRI Room Gas Detection, one must understand the physics of the “Quench” event and its physiological consequences.

The Physics of Catastrophe

Liquid Helium is the most common cryogen used today. While it is inert, its volume expansion rate is staggering:

1 Liters of Liquid Helium = 700 liters of Helium Gas

During a quench, this massive expansion happens almost instantaneously—in seconds. The resulting gas surge fills the MRI room rapidly. Since Helium is lighter than air, it initially rises, but due to the sheer volume and speed, it mixes turbulently, displacing all the breathable air. Nitrogen, if used, is heavier than air and sinks immediately, creating a suffocating blanket at floor level.

The Physiological Effect of Oxygen Deprivation

Human safety relies on an atmospheric oxygen concentration of 20.9%. The human body cannot detect low oxygen; there is no smell, no taste, and no early warning sign of asphyxiation.

The danger thresholds are clear and unforgiving:

| Oxygen Concentration (O₂) | Physiological Effect on Humans | Safety Status |

| 20.9 % | Normal, healthy atmosphere. | Safe |

| 19.5 % | The OSHA/NFPA Minimum Safe Level. Monitoring alarm should trigger. | Warning |

| 16.0 % | Symptoms begin: Increased pulse, rapid breathing, impaired judgment, poor coordination. | Immediate Danger |

| 10.0 % | Loss of consciousness occurs rapidly (within minutes or even seconds). | Life Threatening |

| 6.0 % | Convulsions, permanent brain damage, and death. | Fatal |

The speed and lethality of the oxygen drop mean that staff attempting a rescue, or a patient left conscious during the event, will succumb to the effects before they can safely exit the room, emphasizing why continuous, automated Cryogen Safety MRI monitoring is the only acceptable defense.

Compliance is Mandatory: UAE, GCC, and International Safety Standards

In the healthcare sector across the UAE and GCC, compliance with international standards is enforced rigorously by local licensing and accreditation bodies. A failure to install and maintain certified O₂ Monitoring MRI UAE systems constitutes a major safety violation and can jeopardize a facility’s accreditation.

International Mandates

Reputable systems must meet or exceed mandates set by global authorities:

- NFPA 99 (Health Care Facilities Code): This code dictates the requirements for medical gas and vacuum systems, setting the baseline for safety in areas where compressed or cryogenic gases pose a hazard.

- Joint Commission International (JCI): As a global standard for healthcare quality, JCI emphasizes Life Safety and Environment of Care standards. During accreditation audits, inspectors rigorously check for evidence of functional and regularly calibrated monitoring systems in all high-risk areas, including MRI suites.

- The MRI Equipment Manufacturer: The manufacturer’s installation manual almost always mandates the installation of an independent O₂ monitoring system linked to emergency ventilation.

Local Compliance and Liability in the UAE

For healthcare operators in Dubai, Abu Dhabi, Riyadh, and Doha, the compliance landscape is managed by powerful local bodies:

- Dubai Health Authority (DHA) / Department of Health (DoH, Abu Dhabi): These regulatory bodies demand that all licensed healthcare facilities demonstrate compliance with international life safety codes like NFPA.

- Hospital Audits and Licensing: Documentation showing the calibration certificates and the integration success of your MRI Room Gas Detection system is essential for passing mandatory annual audits.

- Legal Liability: In the event of a quench incident, the presence of a certified, functioning monitoring system is a critical defense against legal liability and negligence claims. The system acts as the hospital’s independent proof that all reasonable safety measures were in place.

The Technical Solution: Dedicated O₂ Monitoring Systems

Effective Oxygen Deficiency Monitoring in an MRI room demands specialized equipment that addresses two major technical challenges: the extreme cold/low-level gas pocket, and the high magnetic field.

Standard off-the-shelf air quality monitors are inadequate. The system required is a Sample-Draw Oxygen Monitor using specialized sensor technology.

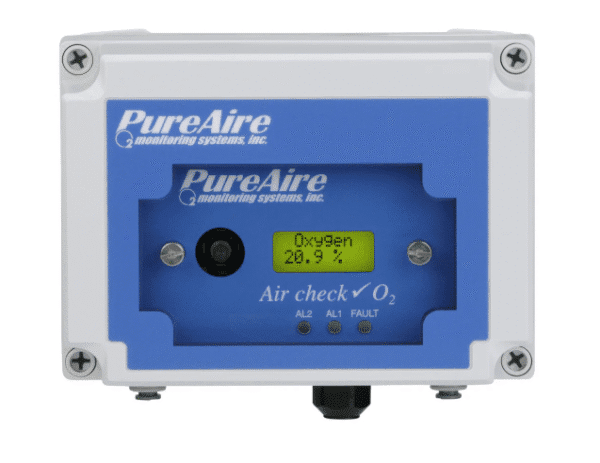

Featured Product: The PureAire Sample-Draw Oxygen Deficiency Monitor

PureAire Sample Draw Oxygen Deficiency Monitor

Stop the Silent Threat: Get the 10+ Year Sensor PureAire Sample Draw Oxygen Deficiency Monitor

The PureAire Sample Draw Oxygen Deficiency Monitor provides continuous, reliable safety for your most critical areas. This high-performance device actively samples the air from hard-to-reach or sealed locations, like an , ensuring your personnel are safe from the invisible danger of oxygen depletion.

Featuring a revolutionary zirconium oxide sensor, this system eliminates the need for frequent calibration and sensor replacements. It gives you an incredible years of service life. This means lower running costs and uncompromising, continuous protection for environments using inert gases like nitrogen (), argon (), and helium () across the and .

Key Features for Uncompromising Safety

- 10+ Year Zirconium Oxide Sensor: Buy with confidence knowing this is the longest-lasting oxygen depletion sensor on the market, providing over a decade of continuous monitoring without replacement. This drastically cuts down maintenance and operational costs.

- Sample Draw Technology: The powerful built-in pump actively draws air samples from up to feet away. This feature makes it the ideal sample draw oxygen depletion monitor for monitoring restricted areas like cryogenic freezers or confined spaces.

- Dual-Level Audible/Visual Alarm: The system features two pre-set alarms at and and a loud horn. This ensures immediate and unmistakable notification of hazardous oxygen deficiency levels, allowing for a rapid response.

- Zero Calibration Required: Install it and trust it! Unlike electrochemical sensors, the sensor technology does not require monthly or yearly calibration, saving your business time and labor costs.

- Reliable in Extreme Environments: The durable design and stable sensor technology deliver accurate readings from to , making it perfect for both and the high temperatures of the .

- Easy Integration: Connect the analog output and dual alarm relays to your existing (), fire alarm panel, or a remote horn/strobe for centralized safety management.

Key Features in a Nutshell:

The PureAire system is built specifically to address the unique demands of cryogenic safety:

| Feature | Technical Advantage | Life Safety Benefit |

| Zirconium Oxide Sensor | Uses high-performance Zirconium Oxide (ZrO₂), which is a non-depleting, maintenance-free technology. | Reliability & Lifespan: Unlike common electrochemical sensors that deplete and require replacement every 1-2 years, this sensor lasts 10+ years, ensuring uninterrupted monitoring. |

| Sample-Draw Mechanism | The sensor and electronics cabinet are placed outside the MRI suite. Air is drawn via narrow tubing from the detection point inside the room. | Magnetic Immunity: Eliminates all issues related to sensor damage or interference from the powerful magnetic field, guaranteeing accurate readings. |

| Dual Alarm Relays | Includes multiple programmable electrical relay contacts for Warning (19.\% O₂) and Danger (18.0% O₂). | Automated Response: Triggers immediate, mandatory actions: emergency ventilation activation, automatic door release, and warning lights. |

| Digital Display | Bright, easy-to-read digital readout for continuous real-time O₂ status. | Immediate Visibility: Staff can instantly confirm safe operating conditions before starting a procedure. |

Why Standard Monitors Fail in MRI Suites

- Electrochemical Sensor Failure: Traditional O₂ sensors contain a liquid electrolyte that is sensitive to pressure, temperature, and is actively “consumed” by oxygen. Their lifespan is short, and they are susceptible to damage from the magnetic field, leading to costly false alarms or, worse, failure to alarm.

- Sensor Placement Issues: Due to the magnetic field, standard fixed-head sensors must be placed far from the magnet (the source of the hazard). The Sample-Draw system solves this by locating only a simple, plastic air intake tube near the magnet, while the sophisticated electronics remain safe outside.

- Low-Level Danger: Since cryogenic gases sink, the sensor must be placed near the floor. The Sample-Draw system ensures that the air intake is positioned at the critical 0.5 meter level where the danger is greatest, pulling air sample to the sensor cabinet located at eye-level outside the room.

Installation and Placement: Best Practices for Maximum Protection

Proper physical placement is as critical as the technology itself. A poorly installed O₂ Monitoring MRI UAE system is a liability.

Sensor Intake Placement (The Critical Zone)

The most lethal concentration of escaping cryogen gas occurs low to the floor and close to the quench vent pipe.

- Location: The air sampling inlet tube must be installed at a height of 0.5m to 1.0m (1.5 to 3 feet) above the finished floor, and as close as safely possible to the MRI scanner and the quench line exit.

- Visibility: The sensor tube inlet is discreet and safe to place near the magnet as it contains no electronics.

Alarm and Display Placement (The Warning Zone)

The alarm sequence must prioritize warning personnel outside the room to prevent them from entering a life-threatening atmosphere.

- In-Room Indicator: A light status panel can be placed inside the room (outside the 5-gauss magnetic field line) to notify occupants immediately.

- External Alarm Panel: This is the most crucial component. The main display unit and high-decibel audible alarm must be placed immediately outside the entrance door of the MRI suite. This is the last safety checkpoint for staff entering or approaching the room.

- Integration: The system must be wired to the facility’s Emergency Ventilation System and, ideally, the Building Management System (BMS) to provide central alerts.7

Maintenance and Calibration

For ongoing JCI and DHA compliance, the system must undergo regular certification:

- Calibration Frequency: Annual calibration checks are mandatory. The PureAire’s non-depleting technology significantly reduces the risk of calibration drift but regular validation is required for auditing purposes.

- Documentation: Every hospital must maintain detailed records of installation, commissioning, and subsequent calibration reports signed by a certified gas detection engineer.

Case Study: Oxygen Deficiency Monitoring in MRI Room at Cleveland Clinic Abu Dhabi

As the leading regional expert in high-stakes gas detection, GasDetectors.ae has successfully commissioned life safety systems in the most demanding environments across the GCC. Our installation at the world-renowned Cleveland Clinic Abu Dhabi (CCAD) serves as the ultimate proof of our expertise.

The Challenge at CCAD

Cleveland Clinic Abu Dhabi is a state-of-the-art facility operating under the highest international safety standards.9 The challenge presented to our engineers was two-fold:

- Zero-Compromise Safety: The system had to be $100\%$ reliable, immune to the powerful magnetic interference, and certified to meet all global and local health authority compliance mandates.

- Complex Environment: We had to install and commission the system with minimal disruption to the hospital’s operations, ensuring integration with the complex Building Management System (BMS) and the MRI vendor’s specific requirements.

The Solution: Deploying PureAire Expertise

GasDetectors.ae selected and commissioned the PureAire Sample-Draw Oxygen Deficiency Monitor precisely because its Zirconium Oxide sensor technology provided the long-term reliability and magnetic immunity required for a facility of this stature.

Our certified engineers executed the installation based on strict best practices:

- Strategic Placement: The air intake sampling points were strategically placed at floor level near the quench pipes of all active MRI suites, ensuring we captured any escaping cryogen gas immediately at the source.

- External Control: The main electronic control cabinets were securely mounted in the hallway, safely outside the 5-gauss exclusion zone, and labeled clearly for staff visibility.

- BMS Integration: We successfully commissioned the relay outputs to the CCAD’s BMS, ensuring that the facility’s centralized safety team received immediate digital alerts and that the emergency ventilation automatically engaged upon a low-oxygen warning.

The Result: Verified Compliance and Trust

The installation was signed off by the CCAD safety team and passed subsequent international and local compliance audits with zero findings. By providing a reliable, low-maintenance, and fully certified solution, GasDetectors.ae not only protected the facility’s staff and patients but also delivered peace of mind and cemented our position as the trusted partner for complex life safety solutions in the GCC healthcare market.

We are proud to stand behind the safety standards of world-class institutions like Cleveland Clinic Abu Dhabi.

Choosing Your Partner:

Protecting your facility’s staff, patients, and multi-million dollar MRI investment requires a partner who understands both gas detection technology and local healthcare compliance.

GasDetectors.ae is the specialized provider for MRI Room Gas Detection in the UAE and GCC region:

- Niche Expertise: We focus exclusively on industrial and life safety gas detection, ensuring our knowledge of NFPA, JCI, and local health authority requirements is unparalleled.

- Certified Products: We supply and service only certified, high-quality systems like the PureAire Sample-Draw Monitor, designed specifically for magnetic environments.

- Turnkey Solutions: We handle the entire process—from initial site assessment and system design to certified installation, commissioning, and mandatory annual calibration reporting required for your audits.

Don’t wait for a safety incident to expose a lapse in compliance. A reliable Oxygen Deficiency Monitoring system is the single most critical investment you can make in your MRI suite.

Conclusion:

The risk of a cryogen quench is a stark reality in any MRI facility. While the event itself is rare, the consequences of an unmonitored quench are catastrophic and immediate. In the regulated healthcare environment of the UAE and GCC, compliance is a minimum standard, and life safety is the ultimate priority.

By selecting the right technology—such as the PureAire Sample-Draw Oxygen Monitor—and partnering with certified regional experts, you guarantee continuous safety, protect your staff, and secure your facility’s accreditation status.

Take the first step toward guaranteed compliance and zero-risk operation.

👉 Contact our certified engineers today for a complimentary site assessment and a detailed proposal for Oxygen Deficiency Monitoring in your hospital facility.